The desalted water station of the first phase of the integrated industrial chain project of functional new materials with an annual output of 800,000 tons by Sichuan Yongying New Materials Co., Ltd. makes full use of the condensate in the enterprise system, and after cooling, iron removal and oil removal, it is recycled for use in the desalted water station as the source water of the EDI membrane system, saving the use of primary water, reducing the scale of the front-end ultrafiltration and reverse osmosis systems, and reducing the investment cost of the system. The reverse osmosis concentrated water and workshop backwash drainage generated by the desalted water station are uniformly recycled to the wastewater pool and transported to the reuse water station for recycling, achieving zero emissions, high recovery rate, environmental protection and energy-saving industrial development trends. This systematic water treatment solution not only saves capital costs for the project construction of Sichuan Yongying New Materials Co., Ltd., but also provides a valuable reference example for the water treatment engineering construction of similar projects.

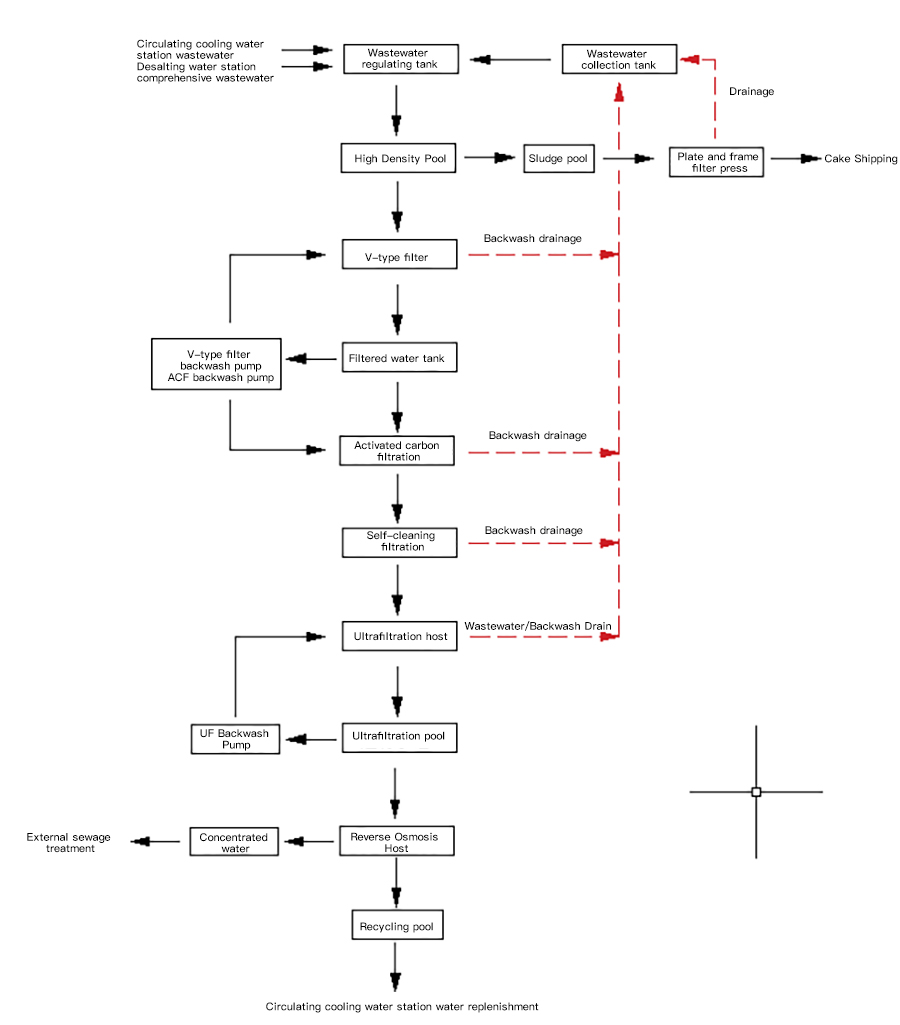

The reuse water station of the first phase of Sichuan Yongying New Materials Co., Ltd.'s 800,000-ton annual integrated industrial chain project is mainly composed of production wastewater from the desalted water station and sewage from the circulating water station. The main feature of the production wastewater is high hardness. Based on the characteristics of the water quality, our company adopts a double alkali hardness reduction process, and then configures a membrane treatment process to recycle the water quality. The backwash drainage of the reuse water station workshop and the supernatant of the high-density filter press system flow into the wastewater collection tank together. As the source water of the reuse water station, the water resources are fully utilized. The fresh water produced by the membrane system is used as the supplementary water of the circulating water system, and the concentrated water is discharged into the wastewater station and discharged after being treated to meet the standards. This set of process routes has stable operation, small footprint, and high automation procedures. It provides a very valuable reference example for the construction of water treatment projects of the same type.